How To Wax Cross Country Skis

Author: Bert Hinkley, nordic ski expert at Webcyclery & Webskis

Last updated: November 2022

Bend, Oregon, is an incredibly popular place for cross country skiing (also called nordic skiing) among both avid enthusiasts and olympic athletes. That means we know our stuff here at Webcyclery, and we hope to make your xc ski waxing experience as easy as possible with this helpful guide.

We cover everything you need to know about wax and waxing, from the basics of understanding how ski wax works, to choosing the right wax for the job, to explaining how to properly wax your skis, and more. Start scrolling from the beginning, or use our menu buttons to jump to the section you want to read.

How To Wax Cross Country Skis

How To Apply to Your Skis (Carefully!)

After you read this step by step guide you'll be ready to have a blast on wicked fast boards. Leave your friends in the dust. They will think you have huge skills (which is great for your ego) and lots of people will think you are super smart. Just re-read this article every day and then make up answers to their questions. Remember they are asking and so they know less than you do.

1. Start by cleaning the base

This can be achieved by first brushing the bases with a brass or medium steel brush. It gets the old wax out of the structure.

If your skis were last used in the spring and sat around all summer in the garage without having been cleaned and waxed, you may want to apply a thickish layer of warm yellow wax and scrape it off the base while it is still warm (hot-scrape) to remove dirt particles. (See more about wax application below).

You can also use a gentle solvent (SOLDA Eco 2000), or mineral spirits applied to a clean rag and wipe the skis bases. This removes old wax, dirt, dust and grime. It will also leave the bases dry and in great need of wax. Follow this by brushing with a fine brass brush from tip to tail.

2. Select your wax and set the iron temperature

Most wax packages have a suggested iron temp on the back. If the iron is smoking it is too hot. Hot irons damage ski bases and the glues that hold the skis together.

3. Coat the base

Hold the wax against the iron for a moment then rub the semi-melted wax on the ski base. Coat the whole base. Then spread the wax with the iron moving it from tip to tail. Keep the iron moving, taking about 15 - 20 sec to go down the length of the ski. The ski should feel warm, but the wax should solidify right behind the iron.

After one pass do this again and further smooth the wax. Set the ski aside and coat the other one with wax (unless you ski on only one ski). It is a good idea to scrape the wax from the groove of the ski (grooves if it is a Rossi) while it is still warm.

4. Scrape the wax off

That’s right, put it on then scrape it off. You want the base of the ski, not a thick coat of wax, to run on the snow. The wax is used to harden or soften the base to deal with the crystal, moisture and friction. Use a plexiglass scraper to remove most of the wax from the base.

Hold the scraper with two hands, index fingers on top, thumbs on the back, facing you, and second fingers on the bottom corners. Use smooth, overlapping strokes to remove most of the wax moving from tip to tail on the ski.

5. Brush the bases

Start with a stiff bristle brush of steel or nylon or brass. Finish with softer brushes until you have achieved a nice shiny surface with the structure of the ski visible and no wax glops (technical term) on the base. Always brush from tip to tail if you are using a brush with metal (steel, copper, bronze, brass) using moderate, even pressure in overlapping strokes. Nylon and natural fiber bristle brushes can be scrubbed back and forth on a ski without damaging the bases.

Don't have all the gear mentioned above?

More Ski Waxing Info & Tips

Dry rub waxing

We have, lately, been using alternative waxing techniques to apply the wax. One way that has produced very good results, is to dry rub the wax on a clean base. Then use a roto-cork to spread and bond the wax to the base. Let the ski cool and then brush with a nylon polishing brush. This method is being used by many coaches for application of wax to many pairs of skis on the morning of a race. It involves no hot iron, no scraping. It seems to be durable enough for 5 -10km of skiing, depending on snow type.

Liquid waxing

Most wax companies are also developing liquid waxes. The paraffin base is suspended in some kind of solvent. When the liquid is applied to the ski base it should be allowed to dry. This will vary depending on the type of solvent used. It is recommended that the liquid be allowed to dry completely. This is a fairly short time for some and overnight for others. Applying the wax the night before is best. Once dry, the skis can be roto-corked and brushed. If pressed for time, just brushing with a soft nylon brush to finish is fine.

Understanding Cross Country Ski Wax

The idea of skiing is to glide on snow. Skis that don’t glide require more energy to make them move, they are also harder to turn and just not much fun. So, keeping the bases fast is important.

The glide-factor is influenced by laws of physics and chemistry. Not all snow crystals are created equal.

Cold snow crystals are hard, like sand, and the friction between the snow and the base often prevents glide.

Warm, wet snow provides lots of moisture that creates suction. Ever put two wet glass surfaces together? They want to stick together, suction.

So the reason for waxing is to adjust the ski base to deal with the type of snow you find on the trail.

In this Ski Wax Basics section, we'll talk about three main elements and concepts: snow, ski bases, and friction.

Snow Crystals

Again, not all snow crystals are created equal. Most of us know what snowflakes look like. Snow crystals also change over time. Those that are new and cold have sharp points that influence the friction between the snow and the ski base.

As crystals age, they lose those points, especially when air and snow temperatures are warm. The points break off or are compressed and the crystals become more rounded. They transform. Transformed snow is generally faster than new snow. It can also be fine grained snow, windblown, or even thawed and refrozen.

Man-made snow is dense and abrasive. The crystals are harder than most natural snow. Each snow will call for a bit of a difference in wax choice

Ski Bases

Wax will be applied to the base of the skis to keep them gliding well. Ski bases are made of a plastic material commonly known as P-Tex (Ultra High Molecular Weight Polyethylene).

This polyethylene plastic has microscopic spaces between the molecules of polyethylene. When wax is applied it is “absorbed” into these spaces and influences the glide quality of the base on the snow.

Modern ski bases are then finished with what is known as a structure. This is a texture that is applied to the ski base with a process called stone-grinding. Skis that are intended for cold snow are ground with a fine and generally shallow grind.

They look very smooth to the eye. Skis that are ground for wet snow have a much more aggressive grind. These “channels” in the base of the ski allow moisture to move away and prevent suction (wet friction).

For a more extensive discussion of stone grinding bases, skiers can consult a web site http://www.caldwellsport.com/ski-service/grinds/.

A book by Nat Brown titled The Complete Guide to Cross-Country Ski Preparation also a good resource.

Friction

Although friction that occurs between the ski base and snow is generally understood as a single entity, there are a number of factors that need to be understood when thinking about friction:

- Dry friction: where dry snow particles touch the base. This occurs in cold conditions. Consider cold to be air temperature below 15 F ( -10 C).

- Wet friction: when a lot of free water is present between the ski base and the snow. This moisture adheres to the base and creates suction. Although this can occur under many conditions, it generally happens when air temperatures are above 20 F (-6 C).

- Static electricity friction: when an electric charge is generated on ski bases through movement on the snow, usually in cold, dry conditions.

- Dirt friction: when hard dirt particles in the snow surface penetrate the base.

Wax companies have done a ton of research on wax and the temps printed on the package are the best guide.

How To Choose Cross Country Ski Wax

Choosing the best cross country ski wax can seem complicated, but it doesn’t have to be. The main things you need to consider are the style of wax you need and the conditions you’re skiing in. From there, you can make additional choices regarding the chemical composition and application of the wax based on personal preference.

We’ll get started with the easy decisions and get into the more complex ones as we go.

Cross country ski wax styles

There are two main styles of cross country ski wax: kick wax and glide wax.

Kick wax helps you propel yourself forward (or kick) along the track by providing friction so your skis can grip the snow and give you something to push off against. Kick wax is applied to the “kick zone” of classic cross country skis, which is basically the middle section of the ski underneath the bindings and boot. Skate skis do not require kick wax.

Glide wax by contrast reduces friction between the ski and the snow surface and enables the ski to glide faster and farther. All cross country skis use glide wax, and without it, you’ll be working way harder than you need to while your friends glide past you with less effort. There’s no more frustrating feeling.

If you want to learn more about the difference between classic and skate skiing, check out our guide to the Types of XC Skiing.

Choosing XC ski wax based on the conditions

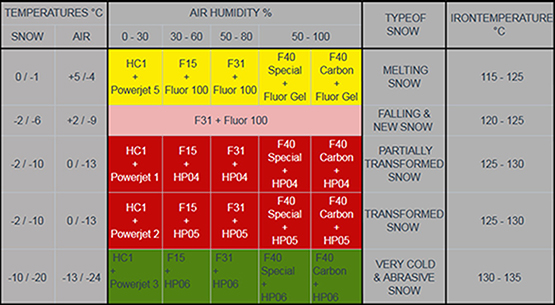

Besides choosing the appropriate kick/glide wax styles, the most important consideration when choosing the best cross country ski wax is the conditions you’re skiing in. Air and snow conditions can vary greatly with different levels of temperature and moisture, so you’ll want to apply a wax that’s weather appropriate.

Choose by color

Warm waxes are colored with warm colors and used for warmer conditions. Cold waxes are colored with cold colors and used for colder conditions.

The coldest waxes are blue and green (like an icy stream in the deep forest). Warmest waxes are yellow, orange and red (like a summer sunset).

Choose by snow type

To choose the right wax you need to know the temperature of the snow, the air, the humidity and the age of the snow (age determines the shape of the crystals; like us, old snow crystals are rounder, less sharp). You also need to know if the snow is dirty.

You can guess at most of this Look at the air temp. In the morning the snow will be just a bit warmer. In the afternoon, the snow will be just a bit colder.

Squeeze a snowball. If it stays together, there is plenty of available moisture. If the snowball is powdery and falls apart it is dry.

Look at the snow crystals on your glove. You can see if they are new, pointy crystals or rounded, transformed crystals. Not rocket science.

Then look at the wax box. It will tell you what the wax is good for. I have to look all the time; I have not yet memorized the temp ranges. Luckily, there is a lot of overlap of temperature ranges that makes hitting the wax easier.

How to wax for extra cold snow

OK, what about cold snow? It is winter, you know. With cold snow you don’t get that thin water layer. What you get is snow that is like sand, hard and the crystals are sharp little devils that try to grab soft ski bases. It is like skiing down an 80-grit slope.

What you want to do is harden the base with hard wax. The ski wax industry figured out how to add synthetic hydrocarbons to harden the basic paraffin waxes. These, when carefully melted onto the ski base, reduce the friction factor.

Choosing between different chemical compounds

Not all ski waxes are made with the same chemical compounds, and the different types of wax interact with snow a bit differently. Which type you choose depends largely on personal preference. Here are some tips that can help you decide which type of wax to go with.

Hydrocarbon ski wax

Hydrocarbon ski wax is inexpensive and for most people they work fine to keep ski bases from oxidizing and getting slow. Remember warm temps-warm color wax. SOLDA HC waxes are hydrocarbon waxes. No Fluoros.

Fluorocarbon ski wax

Fluorocarbon additives not only repel water, they also repel dirt and last longer than hydrocarbon waxes. The higher the humidity and available water in the snow, the more benefit is seen in highly fluorinated waxes.

They help repel the moisture created by the energy of friction between the snow and the ski. When snow is not too cold (32 down to 21) the ski glides on a thin layer of water. SO…More moisture, more fluoro.

SOLDA numbers preceded by F indicate a fluorocarbon additive in the wax. Higher number, more fluoro. Other companies will label their waxes as HF (high fluor) or LF (low fluor).

The FIS has banned fluoro waxes in competitions. Learn more about Fluoro waxes here.

Non-fluorinated ski wax

More recently, non-fluorinated ski wax is becoming more popular, as it doesn’t contain fluorocarbons that contain perfluorooctanoic acids (PFOA) that have been proven to have harmful effects on humans and the environment. These new non-fluorinated waxes offer great performance and are replacing fluoro waxes in races and in personal use.

Choosing the wax application style

There are also different ways to apply ski wax to your skis. Some wax comes as a solid bar that you either melt or scrape onto the ski, while other wax comes in liquid form. There are benefits to both, so read this section to understand which application style you should choose.

Solid waxes are typically ironed on to the base of the ski. This process deeply penetrates the base and provides great durability that lasts.

Liquid wax is becoming more popular and is typically just as fast as a solid waxing job. Liquid waxing saves time, but it is also less durable and will likely need to be applied more often.

Ski Wax Brands

Ski Wax Kits

Tools

Waxers need waxing tools. Brushes are important. We have a nifty brush display. There is an explanation for the use of each brush on the board. Brushing is one of the most important parts of ski waxing.

Irons for clothes are for clothes, not for skis. Waxing irons have thick heat plates, sensitive thermostats and no holes that let wax into the body of the iron. They may seem costly, but if you just put out $800-$1000 for a new ski package it makes no sense to ruin it all with at cheap iron from Goodwill. I have nothing against Goodwill. I shop for most of my clothing there.

Plexiglass scrapers are used for removing most wax from the bases. They are made by all the wax companies and are pretty simple tools. Keeping them sharp is another lesson.

Groover tools are like pens and look good in a plastic pocket protectors.They are used for removing wax from the groove of the ski.

Find the perfect ski wax tools

Waxless Skis

There's No Such Thing as a Waxless Ski

There are people who have been led to a misconception about recreational classic skis that have a “fish-scale” kick zone. These skis are slow anyway and if the glide zones of the bases are let unwaxed they are basically long, narrow snowshoes.

These skis need to be waxed so they glide along in the track. Gliding on snow is what skiing is all about, remember? So the general “waxless” ski owner wants a no hassle morning of skiing. There is wax for these situations.

SOLDA makes a good, inexpensive Hydrocarbon Paste. It smells, looks and goes on like shoe polish. The foam applicator is in the can. The user wipes this paste on the glide zones, lets it dry a couple minutes while making sure the kids are not running around in the parking lot and polishes the wax with a lint free rag we all carry with us. (Could be done at home 10 minutes before leaving.) This is easy and when the snow is not too cold it works for a while. The wax will not last as long as hot waxing, but is a lot less work and no special tools are required.

SOLDA also makes a line of liquid waxes. The chemical properties have improved and these liquids are easy to apply and last much longer than they used to. They can also be applied to the kick zone of the “waxless” skis so there is not so much resistance to gliding, but the scales still engage and provide kick. So, now I guess we have wax all over the “waxless skis”. Bad name.

Want to see more nordic skiing gear?

Nordic Skiing Buyer's Guide

We've compiled a ton of information on how too choose the best cross country skiing gear into our Nordic Skiing Buyer's Guide. You can find lots of info on nordic skis, nordic boots, bindings, poles, clothing and more. We showcase our favorite gear so you can get the best equipment for a great season. Check it out!

General Wax Sales Guides

HC28

HC28 us a carbon base wax that runs well in old or dirty snow. Put it down as a first under or base for other waxes.

UF7

UF7 is a universal low fluoro wax that runs most of the time in a wide temperature range.

F15

F15 waxes have a bit more fluoro additive than UF7. These are great race waxes in dry conditions.

F31

F31 waxes have more fluoro still and used in humidity conditions of 70-90%. These are good bases for the fluoro powders. Fluoros like to bond to fluoros.

F40

F40 waxes are for the highest humidity conditions. More water, more fluoro.

S20 and S30

S20 and S30 are synthetic cold waxes. They harden bases and provide anti-static properties. Static electricity is a problem in dry, cold snow. They contain no fluorocarbon compounds.

Solda Superglide waxes are non-fluorinated waxes that are proving to glide well and can be applied with the dry rub and roto-cork technique. This also comes in a paste form.

Like SOLDA wax, Swix uses the same basic color scheme. Swix is the largest maker of wax. It is a Norwegian company. Swix CH waxes are inexpensive hydrocarbon waxes. CH10 is warm and CH4 is cold. Numbers go down as temps go down. Makes sense. Swix has stopped producing new fluorinated waxes for the public.

Toko waxes are made in Switzerland. They are also good products and follow the warm to cold colors. They have hydrocarbon waxes and have stopped producing fluorinated waxes. They use a carbon additive to deal with static build up on cold, dry snow. SOLDA uses carbon to do much the same thing.

Why was fluoro wax banned?

Why was fluoro wax banned?

Recently people have become concerned about the use of fluorocarbons in wax. There is mounting evidence that extended exposure to fluoros in wax can cause health issues.

For long-time professional wax techs there has been measured decrease in lung function among those who used fluorocarbon powders without proper protection of a respirator. Other health problems are seen in lab animals subjected to large quantities of fluorocarbon gases. Fluorine is also extremely stable when combined with Carbon and it essentially does not biodegrade.

For these, and other reasons, FIS has announced a ban on the use of perfluorocarbons in ski wax beginning when reliable testing procedures are developed, probably in 2022/23.

All the major wax companies are in the process of developing high quality glide waxes that do not contain fluorine.

Fluorocarbon wax history

In the late 1980s Gino Solda was hanging out with the yachting crowd and they were telling him about the use of fluorocarbon coating on boats because it was hydrophobic (repels water, makes them faster).

He then asked the chemists at SOLDA to start experimenting with fluorocarbons in the waxes. Other companies got the word and Swix came out with the first commercial Fluorocarbon ski wax; I think it was 1988.

Gino’s son, Manleo Solda, a chemical engineer, figured out how to bond the fluorocarbon to hydrocarbon waxes and the rest is history.